Dr Pepper Bottling Plant, Second Ave. & Hickory — ca. 1938

Transfixed by Dr Pepper-laden conveyor belts

Transfixed by Dr Pepper-laden conveyor belts

by Paula Bosse

Before Dr Pepper moved into its fabulous art deco HQ at Mockingbird & Greenville (RIP…), the company’s Dallas bottling works was located at Second Avenue & Hickory Street, from about 1927 to 1948. The building (seen below) still stands.

The images in this post are from a DP manual for bottlers, with numerous photos taken in the Dallas plant. All photos in this post are from that manual (more info is at the end of this post), which every true Dr Pepper superfan (or the dogged collector of obscure soft-drink ephemera) should probably have! All captions are from the booklet.

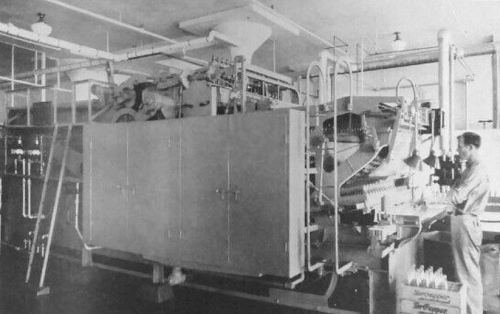

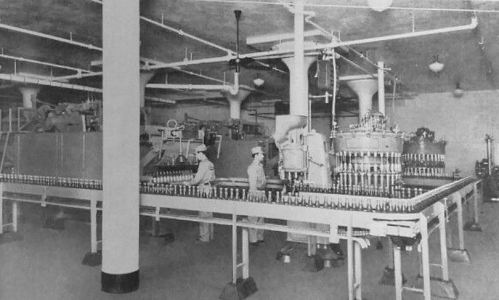

Above, “Interior of Dallas bottling plant in operation.”

Below, “Model syrup factory, bottling plant and general home office of Dr. Pepper Company, Dallas, Texas.”

*

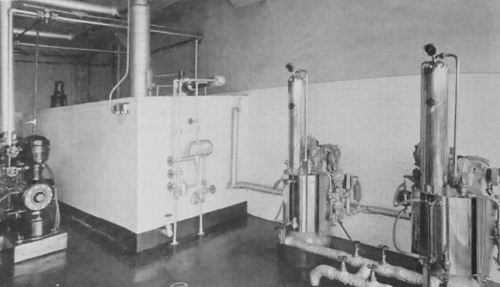

“Water stills, Dallas plant, supplying water for syrup making.”

*

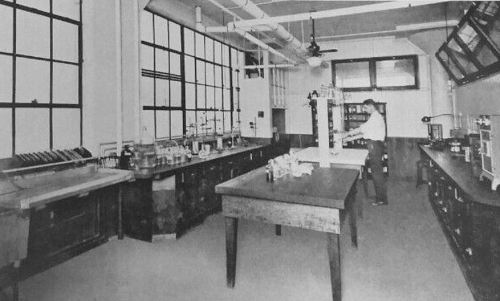

“General view chemical laboratory, Dallas.”

*

“Chief chemist, Mr. H. Buttler, Dallas, Texas” (Howland Buttler is also seen in the photo above).

*

“Water cooler and carbonating equipment, bottling plant, Dallas.”

*

This is my favorite photo: “One section of sugar storage, Dallas — you see a supply sufficient for about a week. Interior view of sugar storage floor, Dr Pepper factory building, Dallas. Only the finest, pure cane sugar is used, a grade and quality superior even to the finest table sugar. Exacting standards must be maintained by refiners to meet our specifications, lest the slightest taste or odor from impurities creep into the Dr. Pepper syrup.” (A few years ago, I stumbled across a crazy story about Dr. Pepper — and other soft drink manufacturers — involved in buying black-market sugar, which was a violation of war-time food rationing, as WWII came to a close. Read about this case in the post “Halloween Party? Don’t Forget the Dr Pepper! — 1947” — scroll to the bottom.) Shout out to Sugar Land!

*

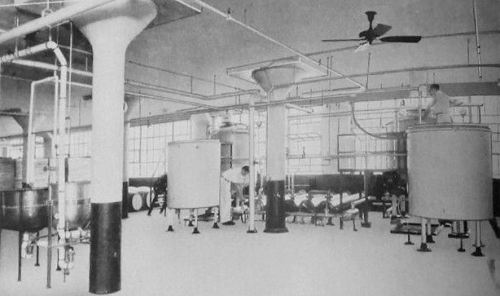

“Syrup compounding and manufacturing unit at Dallas, Texas. Interior view of syrup room, Dr. Pepper factory, Dallas. Note flood of sunshine through modern factory-glass windows; floors, walls, ceilings, as well as equipment, immaculately clean. Glass-lined mixing tanks in center and at right are of 300-gallon capacity, and behind these are 500-gallon steam-jacketed, glass-lined kettles, where hot process simple syrup is made. Entire syrup manufacturing process is modern, efficient and sanitary.”

*

“Modern soaker and washer — one of two units used in Dallas plant.”

*

“Modern crown sifting equipment, Dallas.” (More on crown cork bottle caps here.) (And, weirdly, I wrote about a Dallas company that manufactured those caps in the post “The Crown Cork & Seal Co., Dallas Branch — ca. 1910.”)

*

“Low pressure unit — bottler and crowner.”

*

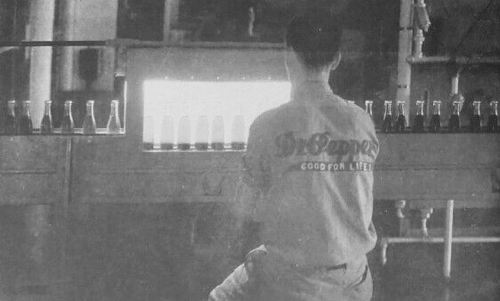

“Final inspection, Dallas bottling plant — ‘candling’ filled bottles.”

*

“Automatic case stenciling machine.” This is an important part of the manufacturing process I hadn’t thought about….

*

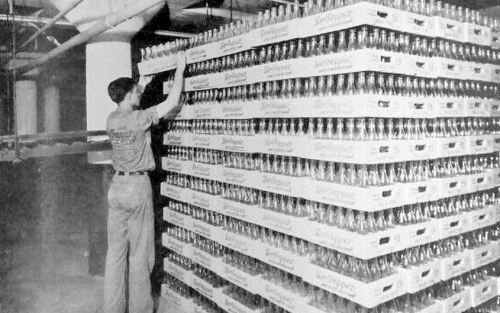

“Bottle storage, Dallas plant.”

*

Battered front cover and title page:

***

Sources & Notes

Photos from “Dr. Pepper Bottler’s Manual: A Manual of Proved Principles and Practices Governing Successful Operation of Dr. Pepper Plants” (Dr. Pepper Company, Dallas, Texas, Nov. 1938); this booklet was found on eBay — for sale for $499.99.

More Flashback Dallas posts featuring Dr Pepper can be found here.

Please consider following me on Patreon, where I post new content daily — for as little as $5 a month!

*

Copyright © 2023 Paula Bosse. All Rights Reserved.